Snactek is a leading food machine manufacturer & supplier in India which provides one stop solution for fryers & frying lines.

-

33, Burhani, Industrial Est, Kondhwa, Pune, Maharashtra 411048

Snactek Office

-

Call Us: (+91) 8048952487

(Mon-Sat)

-

Email: info@snactek.com

Sales & Support

-

Monday - Saturday

(10am - 07pm)

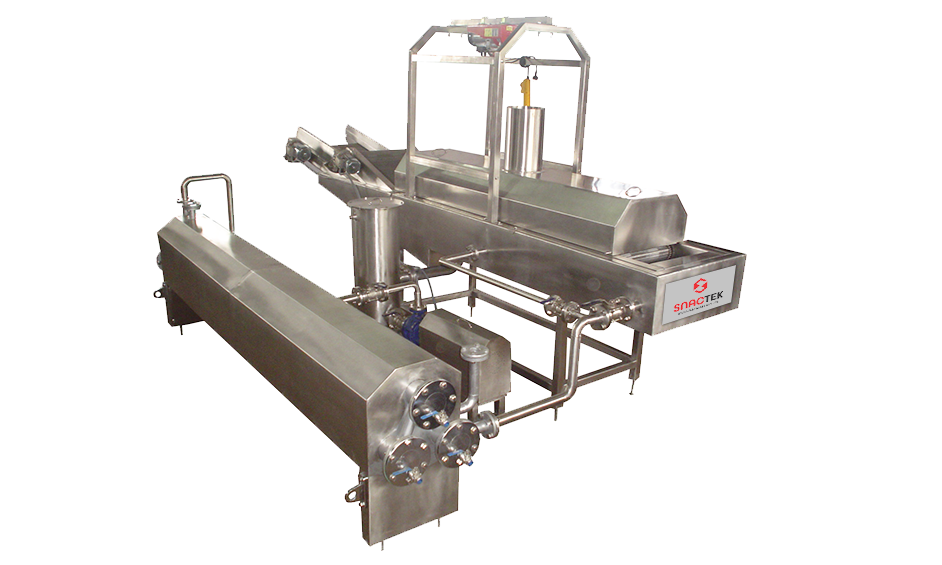

Indirect Fired Continuous Fryer & Frying Machine

Indirect Fired Continuous Fryer Machine:

The continuous fryers are a reliable and universal solution for high-performance frying of a wide range of products by immersing them in hot oil. Easy to use and maintain, minimum consumption of oil and continuous filtering of it, careful processing of products — all these features make these fryers an ideal solution for industrial frying. In our continuous fryers, products are fried by immersion in hot oil and by moving across the frying bath on a single conveyor belt. Hot oil circulates intensely between the heating system and the product, and the oil flows in the direction towards the product. The oil yields its thermal energy to the product very quickly, thus ensuring a similar thermal load as the product would be subjected to if it were constantly being stirred in hot oil. The oil is filtered uninterruptedly with the aid of stainless-steel filters with replaceable stainless cartridges.

Machine options available in this model:

A.CONTINUOUS FRYER - INDIRECT DIESEL FIRED

B.CONTINUOUS FRYER - INDIRECT GAS FIRED

C.CONTINUOUS FRYER - INDIRECT AGRO BASE FIRED

This Continuous frying system is ideally suited for potato chips, banana chips and other low bulk density products like namkeens (salty snacks) Indian sweets, this system is available in different sizes depending upon the production capacity.

Key Benefits:

Positive oil flow with precise Control System:

Has a multi-flow oil injection system for positive oil flow and better heating efficiency. The precise automatic digital temperature control system maintains the oil at the desired setpoint and quickly adjusts to the change in product load.

Proficient Filtration

System:

The filtration systems aids in keeping fine particles in suspension for efficient removal, allowing for the highest oil and product quality. Continuous oil circulation system recycles 100% of the oil ensuring lower operating cost.

Advanced Control System:

The controlled temperature profile will ensure a perfect frying result. Temperature limit switch safely shuts off all gas flow if the fryer temperature exceeds the limit. Frying time and the conveyor speed can be easily adjusted by touch screen PLC operating system.

Oil Quality:

Low oil volume and rapid oil turnover assure fresh product with a long shelf life.

The optimal level is automatically maintained by the level gauge. The fryer has been provided with a well-balanced oil-supply system ensuring the easy transit of the products.

Fresher Product:

The excess surface water from the washed slices is removed leading to a reduction of energy consumption & increases the edible oil self-life.

Our Products

Our Brochures

Snactek is India's leading Indirect Continuous Fryer & Frying Machine Manufacturer.

Get in touch

Connect with Our Experts for Assistance Today

Book a Demo by getting in touch below!