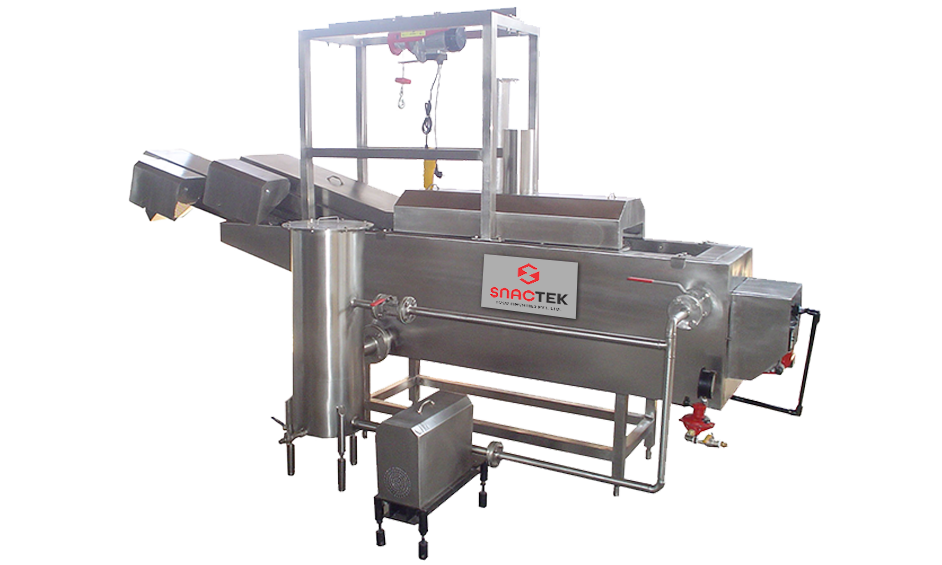

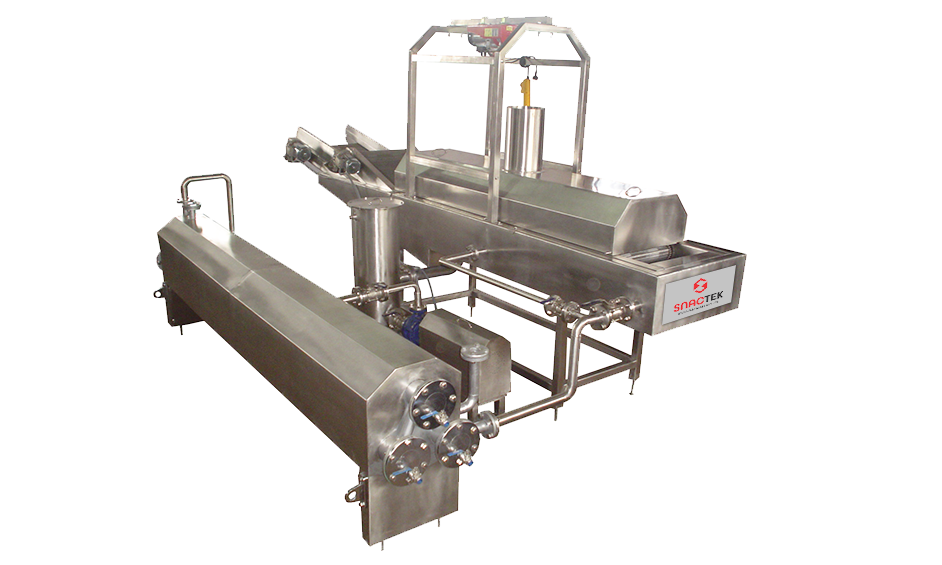

Savor the Taste of Success with Snactek’s Food processing Equipments

At Snactek, we are passionate about providing innovative and efficient food processing solutions. With over three decades of experience, we have established ourselves as a trusted name in the industry. Our commitment to quality, reliability, and customer satisfaction drives us to deliver the best possible machinery for your business.