Snactek is a leading food machine manufacturer & supplier in India which provides one stop solution for fryers & frying lines.

-

33, Burhani, Industrial Est, Kondhwa, Pune, Maharashtra 411048

Snactek Office

-

Call Us: (+91) 8048952487

(Mon-Sat)

-

Email: info@snactek.com

Sales & Support

-

Monday - Saturday

(10am - 07pm)

Extruded Chips & Kurkure making Frying Machine

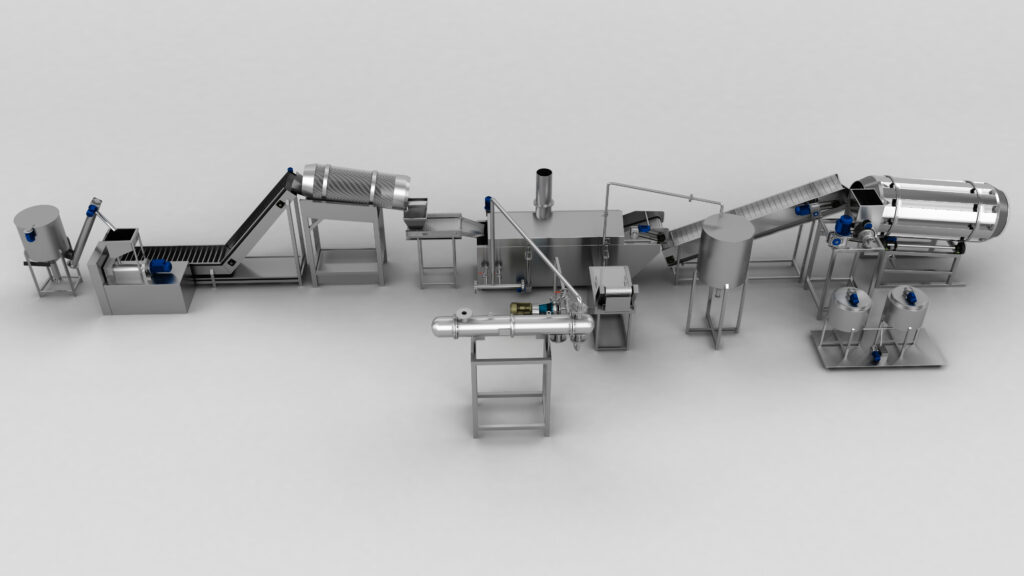

Extruded Kurkure Chips Frying Machine Line:

The working of the Kurkure Chips frying machine line is automated, right from washing and peeling to packaging. The frying duration and the frying temperature can be adjusted to get crunchy and crispy fried chips.

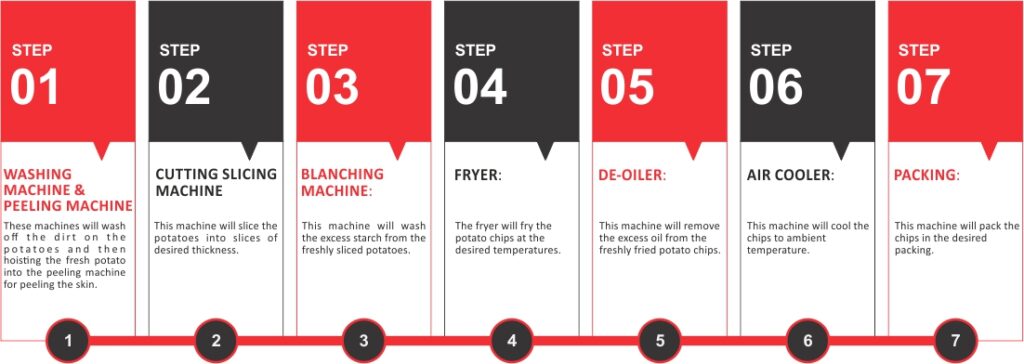

Steps associated with the Extruded Kurkure Chips frying machines line

1. Dough Mixer:

This machine makes the perfect homogeneous mixture of the ingredients which contains potatoes and other materials.

2. Extruder & Cutter:

The dough is then fed into an extruder, then cut into kurkure type extruded sticks or other desired shapes using a precise cutter.

3. Frying:

The fryer’s temperature is manually set, frying the kurkure chips to a desired level for a crispy, delicious flavor and texture.

4. De-Oiling:

To reduce oiliness, the de-oiling machine quickly removes excess oil, improving taste, reducing labor, and enhancing efficiency.

5. Cooling:

Hot, oil-free chips are cooled to ambient temperature in the air cooler before moving to the packing stage, maintaining quality.

6. Packing:

In the final stage, the chips are packed to retain crispiness and prevent oxidation, ensuring a fresh, long-lasting product.

Steps involved in our Extruded Chips & Kurkure Frying Machine Line:

*All our processing lines are custom made and the above list is just to comprehend the process.

Our Products

Our Brochures

Snactek is India's leading Extruded Kurkure Chips Fryer & Frying Machine Line Manufacturer.

Get in touch

Connect with Our Experts for Assistance Today

Book a Demo by getting in touch below!